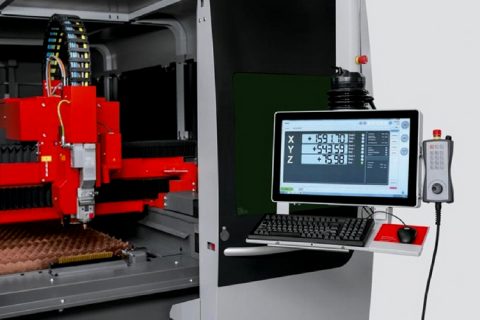

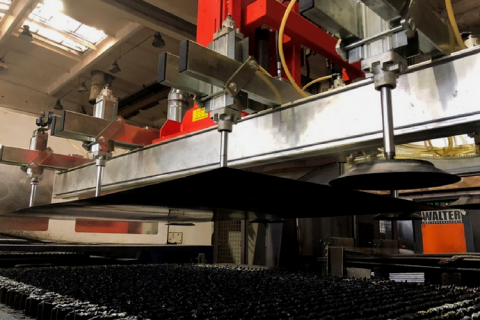

Company Meridian n. S.P.Korolov provides laser cutting services for constructional (carbon), stainless steel and aluminum alloys using a laser cutting system Bystronic BySprint 3015 of Bystronic Laser AG.

LASER CUTTING OF METALS

TECHNICAL FEATURES

| Size of the sheet (the size of a working surface) | 1.5 x 3.0 m |

| Thickness of constructional steel sheet from | 0.5 mm to 10.0 mm |

| Thickness of stainless steel sheet from | 0.5 mm to 4.0 mm |

| Thickness of the aluminum sheet from | 0.5 mm to 2.0 mm |

| Technological gas | oxygen or nitrogen |

| Output data should be in formats | AutoCAD(*.dxf or *.dwg); CorelDraw(*.cdr); COMPASS(*.cdw) | Developed views for cutting are provided on a scale | M1: 1 with overall and high-precision dimensions |

LASER CUTTING OF CONSTRUCTIONAL (CARBON) STEELS

It is often performed with oxygen as process gas. As a result of interaction between oxygen and a heated metal occurs an exothermic reaction of iron oxidation usually with releasing in 3 to 5 times more heat than from the laser emission itself. The quality of surface after cutting is high. Formation of a slight metal flow on the lower edge is typical.

LASER CUTTING OF STAINLESS STEEL

The laser cutting of stainless steel, especially of a heavy thickness, is hampered by the process of slagging cut due to the presence in the metal of alloying elements that affect the melting point of the metal and its oxides. So, it leads to formation refractory oxides that interfere with the distribution of laser emission over processed material. The cutting process becomes more complicate also due to a low flow of molten oxides, which is typical for stainless chromium-nickel and high-chromium steels.

High purity nitrogen which is applied at high pressure (usually up to 14 … 20 bar) is used for high-quality cutting. The cutting process of a large thickness stainless steel requires deepening of a focal point of the laser into the metal. As a result, the diameter of the inlet becomes larger and the flow of gas into the melting zone of the metal increases.

ADVANTAGES OF A LASER CUTTING OF METALS ARE:

- high processing speed allows to accelerate the production process in comparison with the electro-erosion approach.

- the motion trajectory and the optimal layout of details on a sheet is done by the program, which allows to cut parts of any complexity;

- small area of thermal influence provides a slight deformation of the workpiece;

- slight roughness of the cutting edges;

- the productivity of the equipment is oriented for a medium-volume production.

THE COST OF LASER CUTTING OF METAL

Company Meridian provides laser cutting services for constructional (carbon) and stainless steels, as well for aluminum alloys in Kiev. Prices for a lineal meter of a processed material are provided below. Unspecified thickness and stamps of materials are processed with other technologies particularly using HAAS (USA) and MORI SEIKI (Japan) CNC centers.

The cost of laser cutting of metal is calculated for each order individually and depends on: the stamp of a material, the thickness and dimensions of the sheet, the number of items, the length and complexity of the contour, the number of holes and the dimensions of the part.

Cost of laser cutting of constructional (carbon) steel for a serial order (oxygen cutting)

| № | Thickness, mm | Cost, UAH / m |

|---|---|---|

| 1 | 0,5 - 1,0 | 10,00 |

| 2 | 1,5 | 12,00 |

| 3 | 2,0 | 14,00 |

| 4 | 3,0 | 17,00 |

| 5 | 4,0 | 23,00 |

| 6 | 5,0 | 31,00 |

| 7 | 6,0 | 35,00 |

| 8 | 8,0 | 46,00 |

| 9 | 10,0 | 75,00 |

Cost of a laser cutting of stainless steel for a serial order (cutting with oxygen or nitrogen)

| № | Thickness, mm | Cost, UAH / m. Oxygen | Cost, UAH / m. Nitrogen |

|---|---|---|---|

| 1 | 0,5 - 1,0 | 12,00 | 30,00 |

| 2 | 1,5 | 15,00 | 32,00 |

| 3 | 2,0 | 18,00 | 35,00 |

| 4 | 3,0 | 22,00 | 40,00 |

| 5 | 4,0 | 26,00 | 45,00 |

Cost of laser cutting of aluminum alloys for a serial order (cutting with nitrogen)

| № | Thickness, mm | Cost, UAH / m. |

|---|---|---|

| 1 | 0,5 - 1,0 | 30,00 |

| 2 | 1,5 | 40,00 |

| 3 | 2,0 | 50,00 |