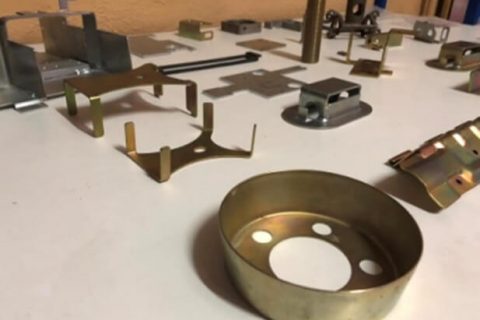

Joint-Stock Company “Meridian” n. S.P. Korolov provides a wide range of galvanic plating for almost all types of materials:

GALVANIZING

GALVANIZING

- multilayered protective and decorative plating of steel parts with copper-nickel-chrome;

- copper-nickel-chrome plating;

- solid, multilayer chrome plating of steel parts with length up to 1800 mm;

- chrome plating of the complex formed molds with additional anodes;

- tin-cadmium alloy plating of steel, aluminum and copper parts;

- chemical nickel plating of aluminum, copper and steel parts;

- chemical oxidation (blacking) of steel parts;

- electrochemical oxidation (anodising) of aluminum parts with colored films;

- chemical oxidation of aluminum parts;

- vibration processing of small parts with Resler apparatus

PLATING PROCESS IN ACCORDANCE WITH CORROSION RESISTANCE CLASSES

CRC1

-Zinc plating with an iridescent passivation Zn // Сn // T0 (5 – 8 μm)

– Powder Coating (70-100 μm)

– Priming or coloring (> 50 μm)

Standard: DIN 50979

CRC2

– Zinc plating, with an iridescent passivation Zn // Сn // T0 (5 – 8 μm), non drum-type method

– Alloy zinc-iron plating with iridescent passivation ZnFe // Cn // T0 (5 – 8 μm)

– Powder coating for phosphated surfaces (70-100 μm)

Standards:

DIN 50979, DIN 50979

CRC 3

Zinc plating with an iridescent passivation and sealed Zn // Сn // T2 (8-12 μm)

– Zinc-iron alloy plating with an iridescent passivation ZnFe // Cn // T0 (5 – 8 μm)

– Zinc-iron alloy plating with an iridescent passivation and sealed ZnFe // Cn // T2 (8-12 μm)

– Powder plating for the following structure: phosphating, cathode electrodeposition and weather-resistant plating (70-100 μm)

Standards:

DIN 50979, DIN 50979

DIN 50979, DIN 50979

ADVANTAGES OF METAL GALVANIZATION

Modern equipment

To ensure the quality and speed of execution of orders, the company has its own automatic galvanic line.

Quality

Application of galvanic coating by our specialists is a guarantee of your hardness, durability, antifriction, anticorrosive and decorative properties.

Cost

One of the advantages of a galvanic method of galvanizing of metal is a relatively small cost.

MODERN PROCESSING EQUIPMENT FOR FINISHED PRODUCTS

Electrolytic zinc plating allows obtaining a steel sheet with a flat surface (without glitter which is typically for hot galvanizing). A layer of zinc (5-10 microns) is determined by the zinc distribution – 10-100 g / m2. The main advantage of non-stop aggregates of electrolytic plating is zinc saving (the thickness of plating is 4-10 times smaller).

Another advantage of the electrolytic zinc plating is the absence of an intermediate layer between the basic surface and the protective layer which improves the mechanical properties and suitability of the steel sheets for stamping. The coating has a fine-grained structure and is more uniform in comparison with the stripe of a hot zinc plating. It has a matted surface that holds any color.

JSC Meridian n. S.P. Korolov is equipped with all necessary equipment, including an automatic zinc electroplating line with a bath size of 1600x900x1200 mm and a pre-processing automatic line for details to achieve a high quality of plating.

The order processing, its placement and execution takes less than 24 hours. The technological process of electrolytic zinc plating consists of three stages:

- Pre-processing of the surface (steel strip) for galvanizing.

- Process of electrolytic zinc plating.

- Finishing and fixing the coating.

PRICE LIST ON GALVANIZING AND COLORING

All orders are checked thoroughly before and after processing. The minimal order is 1 sq.m. or 5 kg of details/material. Large complex details are calculated individually. Details which are come for operating in oil, rust, with a surface oxidation should undergo additional pre-processing of the surface before galvanizing with a coefficient of 1.2

| Name | Cost per 1 sq.m. (UAH) with VAT | Cost per 1 kg. (UAH) with VAT |

|---|---|---|

| Zinc plating | 303.48 | 28.74 |

| Zinc plating of ZAMAK (ZAM alloy) | 29.70 | |

| Etching of aluminum parts and its alloys | 150.00 | 15.00 |

| Thick-layer chromium plating | 1470.00 | 144.00 |

| Copper plating | 1094.88 | 103.32 |

| Copper–nickel (steel, brass) | 1477.98 | 144.60 |

| Chromium plating | 1131.00 | 120.00 |

| Copper–nickel–chromium | 1200.00 | 117.00 |

| Chemical nickel plating (steel, brass) | 1292.88 | 124.92 |

| Chemical nickel plating, bright nickel on aluminum | 852.00 | 84.00 |

| Anodizing without coloring (clear anodizing) | 402.00 | 40.20 |

| Anodizing with dye | 600.00 | 63.00 |

| Chemical conductive oxidation | 165.00 | 16.50 |

| Etching of aluminum and brass parts | 268.02 | 27.78 |

| Copper–tin–cadmium plating | 1068.96 | 116.52 |

| Etching of steel parts | 86.88 | 15.06 |

| Chemical oxidation of steel | 348.00 | 36.00 |

| Chemical oxidation with preliminary etching | 408.00 | 42.00 |

| Vibratory finishing (vibroprocessing) | 45.00 | |

| Electrochemical polishing | 636.00 | 63.60 |

| Chemical nickel, copper, tin–cadmium plating | 1182.42 | 121.62 |

| Zinc phosphate after heat treatment | 143.52 | 14.40 |

| Zinc phosphate after welding | 135.24 | 13.50 |

| Zinc phosphate before painting | 132.60 | 13.20 |

| Powder coating | 189.00 | |

| Screen printing (customer’s material) | 24.60 | |

| Screen printing of nameplates | 53.40 | |

| Stencil production (1 pc.) | 199.20 | |

| Removal of powder coating from small parts | 300.00 | 30.00 |

| Powder coating using customer’s material | 135.00 | |

| Screen printing of complex configurations (1 pc.) | 22.44 | |

| Screen printing of panels and housings (1 pc.) | 37.80 |